The data below is describe to thermal variations in various ways that are used. The solution for dispersing heat from electrical

control units , should be considered from multiple factors such as environment and ambient temperature of control cabinet , size of

control cabinet , power of electric device in control cabinet , surrounding area , energy consumption of each the thermal variations

and etc.

|

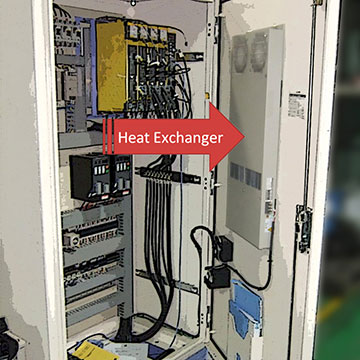

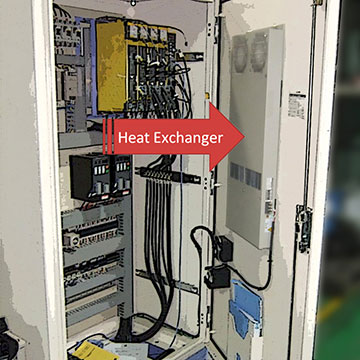

The method of heat dispersion has gained high popularity abroad because of costs that are lower than air-conditioning. However , the user of this method is ineffective when used in countries with hot climate due to heat exchange mechanism of a heat exchanger. The outside temperature must be lower than the control unit's temperature to soak up the heat and reduce the unit's temperature. This condition makes using a heat exchanger difficult in areas with hot climates and it is not surprising that users look for method of heat dispersion to replace it.

|

|

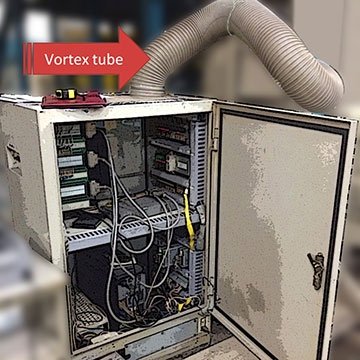

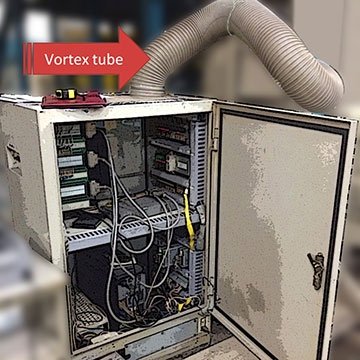

This method of heat dispersion does not lead to many benefits due to its design. It requires a strong air current to be used in areas that require wind. Using air current to blow or sending air current over longs distances is rather difficult. An air pump is used to generate air current which is directed through piping that leads to various points of use. When many points are using the force created by the air pump , the actual force at each destination is divided and lessened. This cause a drop in the efficiency of heat dispersion and the benefits are typically outweighed by the cost.

|

|

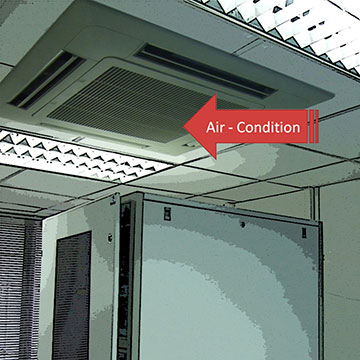

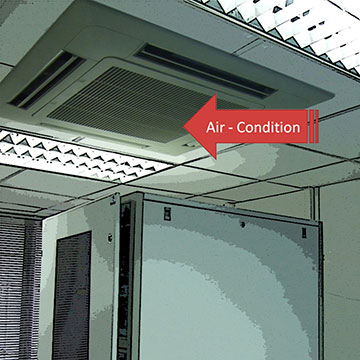

The method is rather high in terms of costs. The first step requires building a surround for the control unit to create a barrier for containing the coolness. Then the next step is installing the air-condition unit which wastes a lot of space. The result is a lower temperature within the room compared to the adjacent areas. However , the heat accumulated within the control unit will have no outlet , which is not fitting of the purpose of having such a unit. Some people try to alleviate this issue by installing a fan to the control unit draw cool air to reduce the heat within the unit. This leads to higher costs and the possibility of contaminants being introduced into the control unit. This cause issues which lead to increased maintenance and repair in the long-term. Also , employee health can deteriorate from working in this rooms that carry the smell of electrical equipment and electronics equipment.

|

|

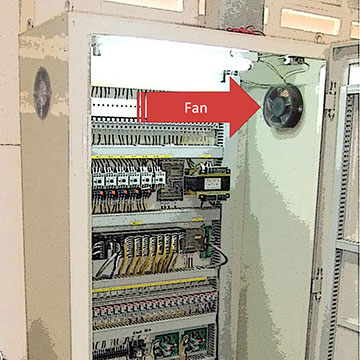

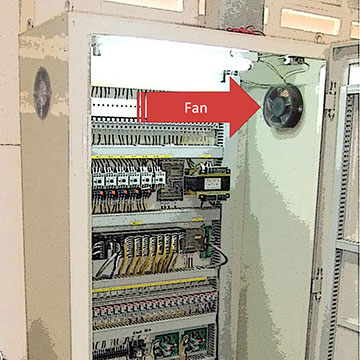

This method to disperse heat is the cheapest alternative compared to other current heat reducing options. It functions with little complexity by installing a fan on the side of the control unit to draw in air from the outside to reduce heat within the unit to prevent accumulation of heat. The amount of heat reduced within the control unit is mainly dependent upon adjacent temperatures. This method uses an open system which can cause detriments such as humidity and pollutants from the surrounding environment. These things can be introduced and blow into the control unit which will surely lead to no benefits.

|

|

We have the best fitting and best value aid in dispersing heat from electrical control units and electronics. We call Cooling unit or the another name of that is Enclosure Cooling Unit , Control Temperature Unit , Panel Cooler , Panel Cooling Unit etc. This is an outstanding solution to solving the issue of heat retention within a control unit and it can also prevent humidity and contaminants better than other methods. It works as a closed system that generates coolness within a component that supplies cold air inside the control unit to disperse heat. The heat is drawn into an air duct to be distributed to the outside. To implement of it is not complicated. One just needs to install the component to an opening cut into the control cabinet and seal the control cabinet to create a boundary for maintaining coolness within. This will help maintain the temperature within the unit and protect it from humidity. This also entry of contaminants and chemicals which can cause damage to components and equipment within the unit.

|

|

The conclusion is that it is very important to consider many factors in selection the best value between the different methods of heat dispersion before making an investment.

|